Core Blocks™

Use them Anywhere

A balanced design approach incorporating functionality, performance and style makes our Core Blocks™ the right choice for performance cruising or racing applications. A tuned 2-stage bearing system provides excellent performance across the full working load range with an integrated thrust bearing feature and the resilience to handle high dynamic or static loads. Acetal & aluminium sheave options, alloy cheeks and stainless fixings complete the durable package.

- Dynamic and high static load performance

- Aluminium sheave options

- Aluminium alloy cheek plates

- Universal head

- Suits pre-spliced lines

- Fully articulated stand-up

CORE BLOCKS™ - FEATURES

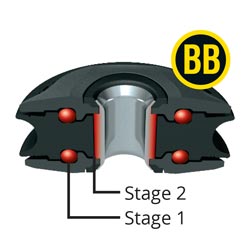

Stage 1 – Under moderate loads, acetal ball bearings ensure minimum friction.

Stage 2 – Under heavy loads, where deformation of ball bearings alone would result in increased friction, a sliding acetal bearing on a polished stainless steel race takes over, maintaining low friction performance.Additionally the ball bearings are configured to act as a thrust bearing between the sheave and cheeks, preventing the sheave from rubbing on the cheeks and causing friction when the line lead in and out of the block isn’t perfect. Particularly important for foot blocks.

Block cheeks are manufactured from the highest quality aluminium alloy for maximum strength. Material optimisation and the cut-away design minimises weight and allows easy fresh water rinsing of salt and debris from the bearings. Cheek design has been further styled with flaring at the block throat and reduced gap between the cheek and sheave, minimising rope wear, and the hollow hub can be used as a becket take-off or tie-up point.

Selected models are available with an aluminium sheave which has a deep groove profile specifically made for use with wire.

The head assembly incorporates a brass bearing washer to provide smooth 360° rotation of the post and shackle. A set screw arrangement allows the head to be locked at 0° or 90°. Shackles are high quality forged grade 316 stainless steel.

Removable becket pins allow fitting of pre-spliced lines. The flush fit becket pin head is kind on deck surfaces and won’t snag lines.

Stand-up models have a low profile linkage that provides full rotation and articulation. A high strength precision cast padeye minimises the footprint and a dedicated rubber boot ensures the block is held upright when not loaded.

Ball Bearing

Orbit Blocks™

LESS FRICTION, ULTIMATE PERFORMANCE

Ball Bearing Orbit Blocks™ - FEATURES

Block cheeks are manufactured from the highest quality aluminium alloy for maximum strength. Material optimisation and the cut-away design minimises weight and allows easy fresh water rinsing of salt and debris from the bearings. Cheek design has been further styled with flaring at the block throat and reduced gap between the cheek and sheave, minimising rope wear, and the hollow hub can be used as a becket take-off or tie-up point.

Ratchet Orbit Blocks™

AWESOME HOLDING POWER

Multiple gripping faces machined into our ratchet block sheaves work in conjunction with our unique cross-hole geometry, delivering up to 20:1 holding power to resist slipping of the loaded line while minimising rope wear. Ball bearings ensure minimum friction under load and a free running sheave when the ratchet is disengaged.

Control switches are located on both sides of the block to remain accessible wherever the block is fitted. In auto mode, the ratchet mechanism engages when load is applied but disengages when released to let the sheet run out freely – ideal for gybing asymmetric spinnakers. In manual mode, the switch is used to set up the block with ratchet either on or off as required.

It is essential equipment on racing dinghies and sports boats, and when you want the ultimate holding power.

- Manual, Auto and Auto+Manual blocks

- Awesome ratchet block holding power

- Simple and secure attachment

- Smooth easing of sheets

- High performance cleating

Ratchet Orbit Blocks™ - FEATURES

Soft Attachment Blocks

SPECIFY THE BEST

Soft Attachment Blocks - FEATURES

Suited to temporary or permanent line deflection, load carrying and snatch block applications including:

- 2:1 Main halyards

- Headsail and spinnaker sheets

- Mast base halyard deflection

- Running backstays

Orbit Blocks™

SPECIFY THE BEST

- The highest strength-to-weight ratio.

- Minimal friction loss, especially when working at high loads.

- Totally reliable and trouble free performance.

- Simplicity of design and construction to facilitate maintenance and servicing.

- Elegant, functional styling and finish.

ORBIT BLOCKS™ - FEATURES

The Orbit sheave has captive Acetal or Torlon® ball bearings for side thrust loads, eliminating the need for side retainer plates. This reduces weight and allows for a wider bearing surface that can accommodate longer Torlon® needles – achieving a substantially higher strength-to-weight ratio.

Orbit Blocks™ - PRODUCT RANGE

Ball Bearing Blocks

BALL BEARING UTILITY BLOCKS

- Use on boats of all sizes for sheets, fine tune and control line applications.

- Highly efficient, low friction bearing systems for optimum sheeting and trimming performance.

- Comprehensive range of sizes and configurations offers solutions for powerful multiple purchase and cascade systems.

- Fiddle block flexibility.

- High performance cleating

- Practical features designed into the blocks provide extra versatility.

BALL BEARING BLOCKS™ - FEATURES

Utility Blocks

ALL-AROUND SOLUTIONS

- All Purpose versions are a great choice for durability and a long service life. They feature self-lubricating acetal polymer sheaves running on polished stainless steel races and perform equally well with dynamic loads and static loads.

- Special Purpose versions are suitable for use with wire rope or where high static load capability is required.

UTILITY BLOCKS™ - FEATURES

Special Purpose Blocks

ULTIMATE HIGH & STATIC LOAD PERFORMANCE

SPECIAL PURPOSE BLOCKS™ - FEATURES

Ultimate Ratchet Blocks™

PRECISION CONTROL

ULTIMATE RATCHET BLOCKS™ - FEATURES

Upright & Pivoting Low Lead Blocks

- High static and dynamic load capacity - BB models have Torlon® needle rollers for axial loads, and acetal ball bearings for side thrust loads

- Upright lead blocks keep lines close to the deck

- Cheek cut-outs for easy bearing cleaning and maintenance

- Blocks can be disassembled for servicing.

T +39 0431 65575 / info@specialrig.com

© Copyright 2022 – Armare s.r.l. – P. IVA IT 02841690304 – All rights reserved